-

Project Heaven – Fabrication

Scroll to Content

ULTRA HIGH STANDARDS

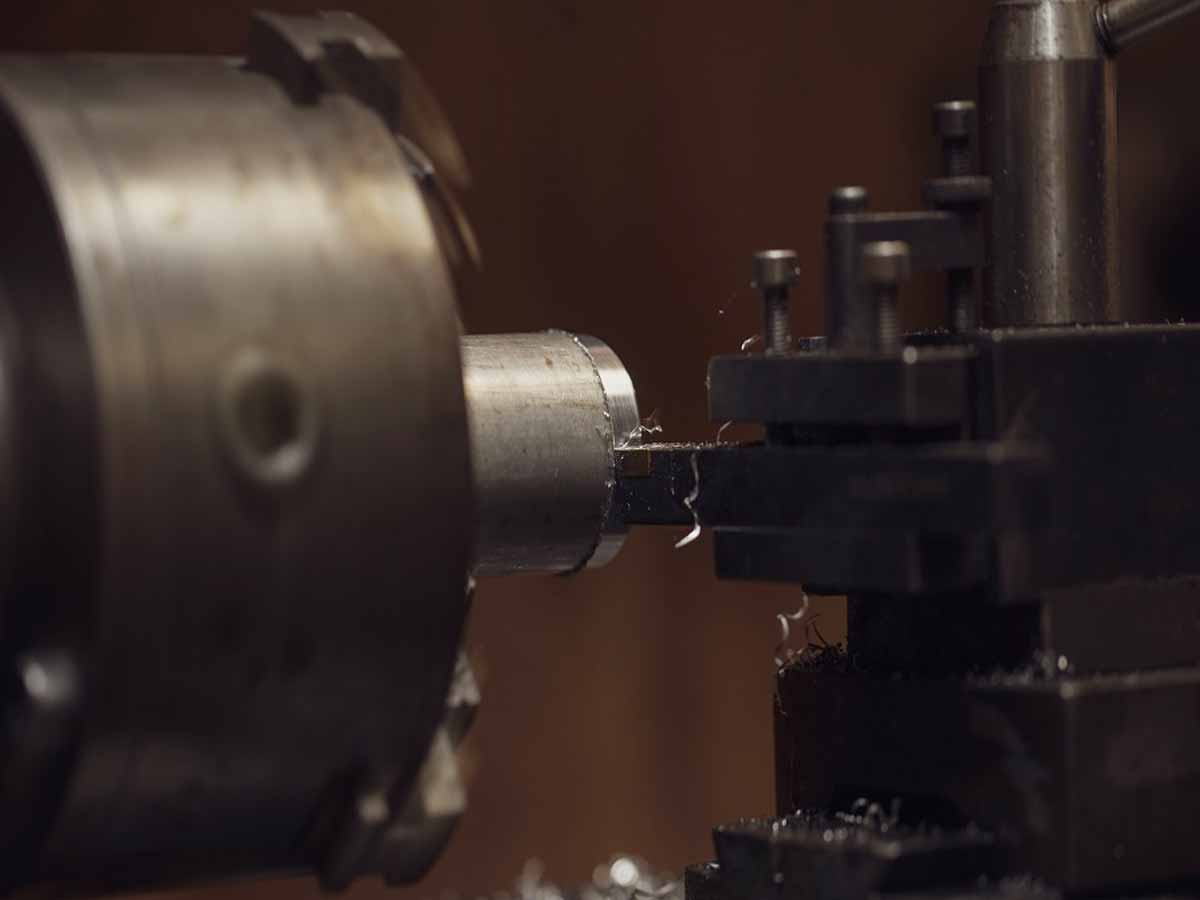

Our fabricators have been expertly trained and have a broad range of knowledge and experience across a comprehensive variety of makes, models, and ages of vehicles. Our team is committed to restoring and replicating the originality of the cars in their care using a range of equipment and techniques appropriate to the original craftsmanship. Our sheet metal forming facilities and tools are extensive – including; CNC plasma cutter, English Wheel, shrinkers, stretchers, benders, and formers. The Project Heaven team has the ability and skills to make any body panel or component in any material. Our onsite, expert materials engineer is always available to review, advise and discuss processes and methodology with our clients. We like to ensure our customers are well informed, knowing the reasons and purposes of techniques used. This gives our clients the assurance they may need to feel their car looks original and is structurally safe. Our full restorations are carried out on a rotisserie to ensure full access during welding repairs and all alignments are carried out on our Celette Jig.

- COLOUR SCANNING

- High Gloss

- Machine Polishing

- AWARD WINNING

Our full restorations are carried out on a rotisserie to ensure full access during welding repairs and all alignments are carried out on our Celette Jig.

FABRICATION

EVERYTHING IS COMLETED IN HOUSE AT OUR AWARD WINNING PAINT AND BODYSHOP

IN HOUSE EXPERTS

2 Room paint shop on site

IN HOUSE EXPERTS

The Project Heaven team has the ability and skills to make any body panel or component in any material

IN HOUSE EXPERTS

Our sheet metal forming facilities and tools are extensive

IN HOUSE EXPERTS

Our team is committed to restoring and replicating the originality of the cars

IN HOUSE EXPERTS

our customers are well informed, knowing the reasons and purposes of techniques used

IN HOUSE EXPERTS

Our full restorations are carried out on a rotisserie to ensure full access during welding repairs and all alignments are carried out on our Celette Jig

SERVICES

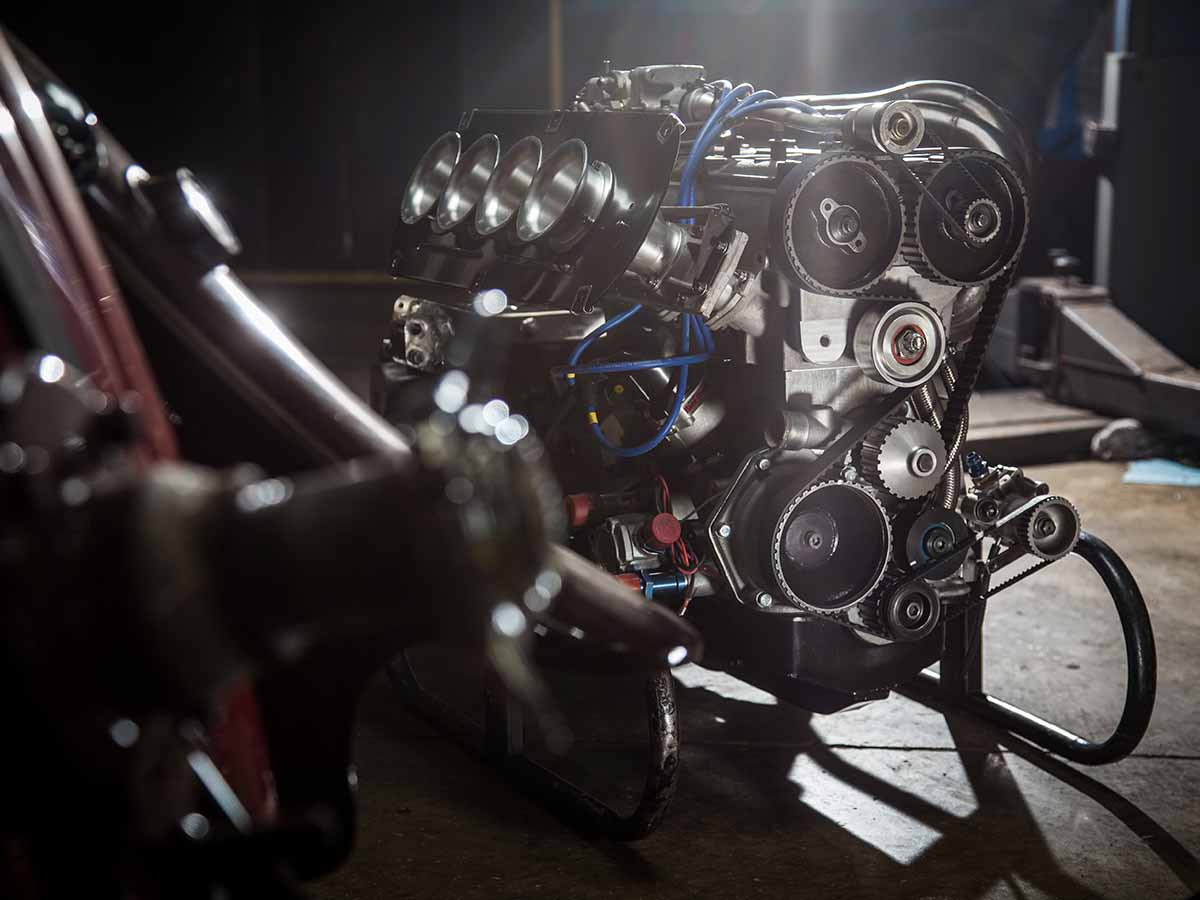

Future proof your classic by undertaking an Electric Vehicle (EV) conversion. We can also retrofit modern technology to your specification

As part of a whole restoration, smaller repairs, or for one-off bespoke work, our in-house trimming service covers all bases

We do more than just complete restorations here at Project Heaven. We regularly perform maintenance services for all vehicles